Oxy-Fuel Welding

Oxy Energy welding (OFW) is a team of welding procedures which sign up with steel’s by warming them when it comes to an energy gas fire or flares when it comes to or without the application of stress and then when it comes to or without using filler steel. OFW, Oxy-Fuel welding consists of any sort of welding procedure that takes advantage of an energy gas integrated when it comes to oxygen as a home heating tool. The procedure entails the melting of the base steel and then a filler steel, if made use of, through the fire created at the pointer of a soldering iron. OFW, Oxy-Fuel welding Energy gas and then oxygen are blended in the appropriate percentages in a blending chamber which might become part of the welding pointer setting up. Molten steel from home plate sides and also filler steel, if utilized, intermix in a molten pool. After air conditioning, they integrate to develop a constant item.

OFW Processes

There are 3 significant procedures within the OFW team:

- oxyacetylene welding

- oxyhydrogen welding

- stress gas welding

There is one procedure of small OFW, Oxy-Fuel welding commercial relevance, referred to as air acetylene welding, where warmth is acquired from the burning of acetylene when it comes to air. Welding when it comes to methyl acetone-propadiene gas (MAPP gas) is additionally an oxyfuel treatment.

Benefits.

There are 3 crucial benefits of OFW welding:

One benefit of this welding procedure is the control a welder could work out over the price of warmth input, the temperature level of the weld area, and then the oxidizing or decreasing the possibility of the welding ambience.

Weld grain shapes and size, as well as weld pool thickness, are additionally managed in the welding procedure due to the fact that the filler steel is included separately of the welding warmth resource.

OFW, Oxy-Fuel welding is preferably matched to the welding of a slim sheet, tubes, and also little size water pipes. It is additionally made use of for repair work welding. Thick area welds, with the exception of repair, are not cost-effective.

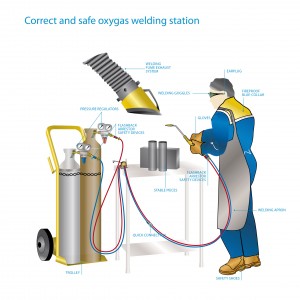

Tools and also Packages.

The devices utilized in OFW, Oxy-Fuel welding is reduced in expense, typically mobile, as well as functional sufficient to be made use of for a selection of relevant procedures, such as flexing and then correcting the alignment of, pre-heating, article home heating, surface area, braze welding, as well as lantern brazing.

When it comes to reasonably straightforward adjustments in devices, guidebook and also mechanical oxygen reducing procedures could be executed. Steels generally bonded when it comes to the oxyfuel procedure consist of steels, specifically reduced blended steel, and also a lot of nonferrous steels. The procedure is typically not utilized for welding refractory or responsive steels.

Oxy-Fuel Gases.

Business gas gases have one usual building: they all call for oxygen to promote burning. To be ideal for welding procedures, an energy gas, when melted when it comes to oxygen, should have the following:.

- High fire temperature level

- A High price of fire breeding

- Ample warmth material.

- A minimum chain reaction of the fire when it comes to base and then filler steels.

Amongst the readily available OFW, Oxy Energy welding energy gases, acetylene (mix of hydrogen and also carbon) most carefully dates all these needs. Various other gases, energy such as MAPP gas, propylene, lp, gas, as well as exclusive gas’s based upon these, have adequately high fire temperature levels, however, show reduced fire breeding prices.

These OFW, Oxy Gas welding gas fires are exceedingly oxidizing at oxygen-to-fuel gas proportions high sufficient to generate functional warmth transfer prices. Fire holding gadgets, such as counterbores on the pointers, are required for a secure procedure and also excellent warmth transfer, also at the greater proportions.